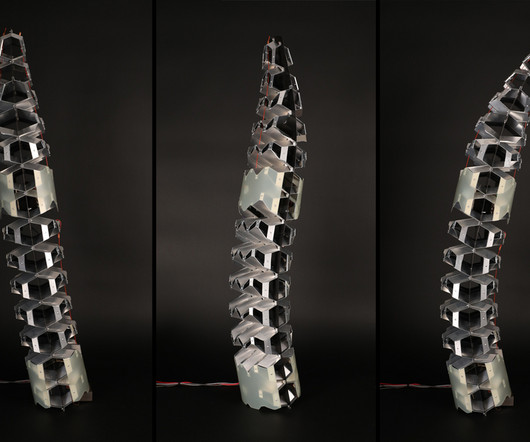

MIT researchers create strong, ultra-light architected materials using kirigami techniques

Archinect

AUGUST 24, 2023

Researchers at MIT have developed a lightweight architected material inspired by the cellular structures found in natural materials such as honeycombs and bones. This manufacturing process is without tooling, like 3D printing. “To make things like cars and airplanes, a huge investment goes into tooling. Image courtesy.

Let's personalize your content