Paint is a pigmented coating used to protect, preserve, decorate, or add functionality to a surface or object. There are a number of paint companies in India offering a wide range of products such as exterior and interior coatings, oil coatings, acrylics, emulsion, enamel, textures, etc. to prevent defects.

In addition, it is a liquid or mastic material. It remains suitable for application to surfaces to color, protect, and provide texture. It categorizes as decorative when applied on-site, or industrial when applied in factories as part of the manufacturing process.

These serve the following purposes:-

- Covering a metal to resist corrosion

- Adding festive trims to a house’s interior

- Protecting the material from oxidation

- Modifying light reflection

- Heat radiation

- Differentiation products or items on the basis of their properties, functions, etc.

These form a solid film when applied to a surface. This film protects the surface from many dangers like corrosion, weathering, chemical attacks, etc. Timber or metal structures can extend their life by coating them with these.

Contents

- 1 Constituents of paint

- 2 Types of paints

- 3 Process of wall painting

- 4 Properties of an ideal paint

- 5 Most common paint defects

- 6 Top paint companies in India

- 7 Conclusion

Constituents of paint

Typically, paint comprises four main components: pigment, binder, liquid, and additives. The application methods depend on the particular kind but can include spray application, brush methods, and electrostatic spraying.

Therefore, the main constituents are as follows:-

Image Source: thomasnet.com

| Also see: Painting a mural: DIY step-by-step digest (19+ Designs) |

Pigment

Pigments refer to the granular solids that impart colour. Dyes or colorants get dissolved in paints and fillers or granular solids, incorporated to impart toughness, texture, or reduce the cost of the product. However, some types contain dyes or a combination of dyes and pigments.

The pigments provide color and opacity. These constitute either natural or synthetic derivatives.

Binder or resin

This component acts as a binder to hold the pigment particles together. In addition, it provides adhesion to the surface. It is the actual film-forming component.

Categorized on the basis of drying or curing mechanisms, these are essential elements of paints.

Solvent

Solvents act as a carrier for the pigment and binder. It may be an organic as well as an inorganic material.

It mainly serves the purpose of adjusting the viscosity. Moreover, it affects the stability, flow, and application of the paints in a liquid state.

That said, MTO or Xylene and water are the main solvents for industrial and water-based coatings respectively.

| Also see: Painting the wall: Learn how to paint like a Pro (Step-by-step guide) |

Additives

Added in small amounts, additives enhance certain properties of paints. This includes ease of application, mould resistance, modification of surface tension, improved finish, pigment stability, and flow properties.

These include catalysts, thickeners, adhesion promoters, emulsifiers, and stabilizers.

Types of paints

Many people are unsure which wall coating is better for their homes. The type you choose is as important as the color of it. It majorly affects the final product.

| Also see: 67+ Wall paint design ideas, colours & patterns for trendy interiors |

On the basis of application area

Interior

Made to cover the interior walls of your home, these contain silicone and epoxy resin.

These kinds of wall paints resist stains and remain easy to scrub without damaging the surface. Moreover, these possess low levels of volatile organic compounds and other harmful chemicals, thus safer for breathing and indoor application.

Paints meant for interior walls, like emulsion, oil coatings, etc. do not suit house exterior applications as they contain organic pigments. These pigments tend to fade away very quickly in sunlight.

Exterior

Meant for outdoor applications, these contain additives to make the wall paint waterproof. In addition, these can withstand prolonged exposure to sunlight without cracking or fading.

Their formulation combats the changing weather. Moreover, like oil coatings and emulsion, these paints resist mold, mildew, fading, cracking, chipping, and more due to the presence of mildewcides and other chemicals.

| Also see: Wall paint: Your guide for the perfect finish (prices incl.) |

Industrial

Industrial paints possess several characteristics which remain easy to manipulate to provide application-specific coverage. These protect metal, wood, and a wide range of other materials.

In addition, these characteristics largely depend on the paint ingredients and the performance specifications of the selected application.

On the basis of the paint surface

Walls

In most cases, the word ‘paint’ refers to wall paint. It protects as well as beautifies the walls. Wall paints add colour, pattern, and texture to the walls.

These are of several types, such as acrylic, emulsion, enamel, metallic, textured, oil paint, etc.

Metals

Specific types of paints prevent rusting and any change in colour of metals. A water-based, as well as oil paint, is suitable for metals.

Thus, alkyd resin-based synthetic enamels and emulsions best suit metal applications. They provide a smooth finish and protection against corrosion.

Wood

Different from the usual wall paints, these paints are specifically formulated for wooden surfaces. They provide better adhesion to wooden surfaces. Moreover, these enhance the wood texture and appeal of the painted surface.

These include specialized emulsions, sealers, varnishes, preservatives, lacquers, chalk powder, etc.

On the basis of paint solvent

Water-based

The most common type of wall paint sold today is water-based. The primary reason is its availability and ease of use.

Although very functional, these can be difficult to use on any surface previously treated with oil paint. Due to the presence of oil, these lose their adhesive property. In such situations, dampen the surface and then scrub it all over with a medium to smooth grit sandpaper. This not only makes it clean, dry, and workable but also prevents the peeling of the new coat.

Oil-based

These suit almost all surfaces. Due to their high durability and rich finish, like emulsions, these are not washable.

However, one needs to be cautious with its usage as these emit strong fumes. These emissions can be quite overwhelming and slightly toxic.

On the basis of function

Distemper

Distempers are durable and economical water-based paints. They majorly constitute colouring agents, chalk, and lime. Considered an excellent budget painting solution, these mostly offer a flat finish.

Distemper paint is thin, non-durable, and economical. Moreover, it can withstand limited and careful washing making it suitable for ceilings. It can achieve nearly any color.

However, distempers are not suitable for application in damp areas such as the kitchen, bathroom, etc. They exhibit poor durability and workability.

Enamel

Produced by adding lead or zinc to varnish, enamel paint dries to a hard and glossy finish. Unlike oil-based paints, these contain glass powder or metal flakes instead of colour pigments.

Achieving a wide variety of colors becomes possible due to the addition of pigments. Characterized by being waterproof and chemically resistant, these offer good coverage, color retention, and ease of application.

The following are some common application areas of enamel paints:-

- Interior and exterior walls

- Wood trims, doors, and flooring

- Windows

- Stairs

- Surfaces like wicker, masonry, concrete, plaster, glass, and metals

Their main drawbacks include slow drying and the requirement of a titanium coating before application.

Emulsion

Emulsion uses polyvinyl acetate and polystyrene as binding agents. They contain driers like cobalt and manganese. Emulsion paints can either be water-based or oil.

Moreover, emulsions are characterized by their fast drying and easy to clean properties. Post application, emulsions offer durability, good color retention, and alkali resistance.

Emulsions are commonly used for interior walls, ceilings, and masonry work. However, some specialized emulsion types suit woodwork as well.

Cement paint

Available in powder form, cement paint is mixed with water to achieve the desired consistency. The base material is white or colored cement, with or without pigments, accelerators, and other additives. Commonly used in rough internal and external surfaces, it is durable and waterproof.

In addition, it has a long drying time, typically 24 hours. To prevent any dampness issues, it must be applied in two coats.

Bituminous paint

Made from dissolved asphalt or tar, bituminous paint has a distinct black colour. It is waterproof as well as alkali-resistant in nature. However, it is not considered suitable for application in areas exposed to the sun.

Generally, it is used in underwater ironworks, concrete foundations, wooden surfaces, and iron pipes. It also helps provide rust resistance when applied to metals.

Aluminum paint

This type of paint is produced by mixing aluminum particles with oil varnish. It is resistant to corrosion, electricity, and weather exposure.

Therefore, it is commonly used for metals and wood. Some of its specific applications include gas tanks, oil tanks, water pipes, and radiators.

Anti-corrosive paint

As the name suggests, anti-corrosive paint is characterized by its chemical resistance. It is made from linseed oil, zinc chrome, and fine sand. Additionally, it possesses a black color, is highly durable as well as affordable. It is typically used for metallic surfaces and pipes.

Synthetic rubber paint

It comprises dissolved synthetic resins and pigments. It has a moderate cost and offers several other benefits, such as chemical resistance, fast-drying, and weather resistance.

Moreover, synthetic rubber paint is used for concrete surfaces in general, including fresh concrete.

Cellulose paint

Cellulose paint comprises celluloid sheets, amyl acetate, and photographic films. Its adhesive property can be improved by adding castor oil. Quick drying time, smooth finish, and resistance to water, smoke, and acids contribute to its distinguishable characteristics.

Therefore, cellulose paint finds its application in cars and airplanes. However, its high price still remains a major drawback.

Plastic paint

This paint uses water as a thinner and is available in a wide range of colours. It dries fairly quickly and offers high surface coverage.

Hence, it is most commonly used on walls and ceilings of auditoriums, showrooms, display rooms, etc. as well as decks and slabs.

On the basis of finish

Matte

It is the most popular interior wall finish. It offers ease of application without an overwhelming surface sheen. An opaque and solid colour becomes achievable by applying more than one single coat. However, matte paint requires regular retouching.

In general, a matte finish is similar to a flat finish but offers superior washability and coverage.

Satin

Satin or pearl finish is highly durable in terms of washability and moisture resistance. It provides protection against dirt, moisture, and stains. Therefore, it is highly suitable for bathrooms, furniture, and kitchens.

However, it is even more prone to show imperfections as it is shiny looking.

Eggshell

An eggshell finish offers subtle shine but not the same smoothness as that of a satin finish. Since they are partially reflective, they do not highlight imperfections. Thus, considered highly suitable for application on interior walls.

They are easy to apply and can often cover well with a single coat. This finish provides great washability. The eggshell finish is valued for bathrooms as it doesn’t peel in a wet environment.

Semi-gloss

A semi-gloss finish is usually used for trimmings such as baseboards, mouldings, and doors rather than walls. It emphasizes the details and elegance of the woodwork.

In addition, it is suitable for heavy usage and offers ease of cleaning. A single coat is usually sufficient for a good covering.

It provides a shiny surface and protection against moisture and wall stains.

High-gloss

This is commonly used on woodwork and metal as it provides a high shine. However, high-gloss paints often require several coats.

High-gloss finishes reflect light and possess a mirror-like sheen. It pairs well with other finishes. Apart from being highly durable and easy to clean, high-gloss finishes tend to show imperfections like scratches, dents, etc.

Flat Finish

This finish generally suits ceilings or walls that are in bad shape. It is useful for hiding imperfections in walls. In addition, it is economical in effectively covering relatively larger areas. However, this finish is not easily washable and is subject to staining.

Process of wall painting

Pre-painting surface preparation

Surface preparation directly affects the final results. First of all, check the surface for any dampness or moisture seepage. If found, rectify the problem at the source and get rid of any damage caused by it.

Next, use sandpaper to remove any flakes and ensure that the surface is free from dust, dirt, or grease. After that, all the cracks should be filled with plaster and sealed properly with a sealant.

Application of primer

Right after evening out the surface, application of a coat of primer starts. Moreover, in case of porous walls or have water damage, the application of primer becomes essential.

It provides a smooth surface for painting. Additionally, it makes the surface less absorbent, thereby enhancing the spreading capacity.

To aid the prevention of mildew, experts recommend using primer on the kitchen, bathroom, and exterior walls. Primer imparts a uniform colour and texture to the surface and provides better adhesion to the topcoats.

However, the type of primer to be used largely depends on the kind of surface to be painted. Therefore, different primers exist for interior walls, exterior walls, wood, metals, etc.

Application of putty

Generally, putties are used for freshly done walls that require total revamping and modification. After the first primer coat has completely dried, a wall putty should be applied.

It fills in minor cracks and surface imperfections, thus providing a protective sub-layer for the final coat. As per the requirement, 1-2 coats of putty can be applied only after allowing the previous coat to dry.

Application of second primer coating

A single coat of primer is required in case of repainting services. However, freshly painted surfaces or surfaces needing considerable leveling require two primer coats.

Moreover, ensure the application of the second primer coat only after the previous putty coat has dried out completely.

Application of final coat

Typically, the achievement of desired finish and colour needs two coats of the finish coating. Application of the first coat takes place in a ‘W’ shape with the help of brushes or rollers. Next comes checking of errors and repairing using putty.

Then, after the application of the second coat in the same pattern, final repairs need to be made if required. Then, the final coat application takes place on the wall to enhance its visual appeal.

Properties of an ideal paint

Painting your house imparts a sense of completion and newness. It increases the aesthetic value of your house. Choosing the right variant is crucial to avoid any painting failures and defects.

Image Source: fordhammaclean.com

List of qualities an ideal paint must possess

Any homeowner must know the following before painting the house:

- Being a determinant of cost, it should possess a good spreading power. It must have the potential to cover the maximum area of the surface by the minimum quantity of the paint. Typically, the brochure given by the manufacturer contains all coverage information.

- When applied to the surface, it should form a thin film of uniform nature.

- The colour should withstand adverse environmental conditions for a long period of time. It should not fade away or change over its useful life.

- It must be able to withstand changes in weather conditions.

- The consistency should be such that it could be easily applied with a brush or a spraying device.

- It should adhere well to the surface to which it is applied.

- Additionally, it should have an attractive and pleasing appearance.

- The initial cost must be fairly low and must prove to be cost-effective in the long run.

- After drying, the surface should not show any cracks.

- It should be corrosion-resistant and protect the material on which it is used.

- It should be such that it dries in a reasonable time and not too rapidly.

- On drying, any signs, such as brush marks, shrinkage marks, cracks, patches, etc. should not be left behind on the surface.

- In addition, it must prevent the growth of moulds and algae.

- The application process should be easy and convenient. Typically, brush or spray painting devices ideally fit their application.

Note: Evaluate the properties of paints at all three stages- before, during, and after the application. An ideal variant will provide the perfect finish and ensure a longer useful life.

Most common paint defects

The main reasons for failure after application are the application tools, techniques, and improper treatment of the surface.

Hence, the paint defects or degradation remain attributed to:-

- Bad workmanship

- Salts and alkalis

- Moisture

- Painting conditions and tools

- Unsuitable surfaces

- Wrong choice of variants

Following are the most commonly occurring defects:

Efflorescence

Image Source: DIY Doctor

Efflorescence is associated with the painting of bricks. Mostly, it takes one of the following forms:-

- Fluffy white deposits caused by sodium, magnesium, or calcium sulphates.

- Formation of white films due to calcium carbonate or hydroxide.

- Hard glossy patches caused by potassium salts.

- Yellowish green stains produced by the presence of chromium salts.

Bleeding

Image Source: Free Stock Textures

Bleeding refers to the diffusion or mixing of a dye from the substrate into the topcoat. Generally, bleeding results in a spot-like discoloration of the topcoat. Common causes of this paint defect are:-

- Use of excessive peroxide with the putty

- Inadequate mixing of the hardener with the putty

- Lack of isolation-sensitive colours

- Improper surface cleaning

- Dissolution of soluble dyes from the old paintwork in the solvent of the repair materials

- Residues from bitumen and tar

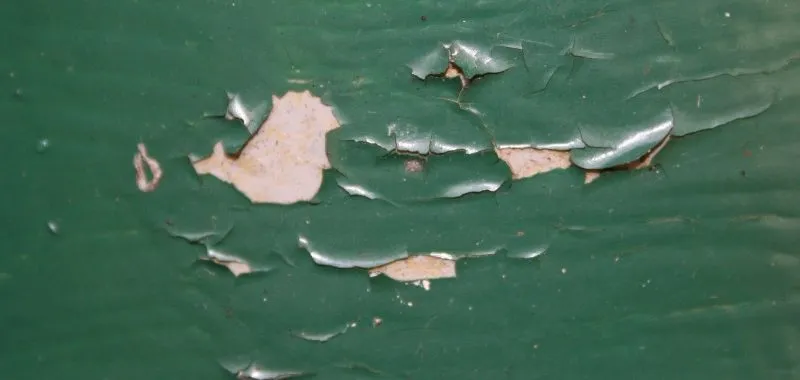

Blistering or peeling

Image Source: British Paints

It occurs due to improper surface treatment and the presence of moisture or dampness in the substrate.

Thus, blistering defect refers to the lifting of the paint film from the underlying surface. In addition, it appears to be a bubble or a blister, usually caused by heat, moisture, or both. Eventually, this leads to another defect called peeling of the paint, if not taken care of.

Causes of blistering or peeling are:-

- Painting in direct sunlight or on a hot surface

- Application of an oil-based or alkyd over a damp or wet surface

- Exposing a freshly coated film to high humidity

- Moisture passing through interior walls from common household sources such as bathrooms, kitchens, etc.

Blooming

Image Source: Harper Painting

Blooming refers to the formation of dull patches on the surface due to improper ventilation, weathering, defective products, etc. In this case, the topcoat of a surface dries out and develops haziness.

Blooming occurs due to the migration of water-soluble compounds. When migrated water compound evaporates from the surface, it appears as sticky deposits on the topcoat.

Eventually, when sticky deposits dry out, it appears as milky and hazy spots on the topcoat causing significant surface irregularities.

Chalking

Image Source: Dulux

Chalking still remains the most common defect seen on the house exterior and interior after painting.

As the name suggests, this defect is the formation of a white, chalky powder on the painted surface. This occurs due to the absence of sufficient oil in the primer. Moreover, all the paints will have this defect if subjected to outdoor exposure over an extended period of time.

Therefore, use weather-resistant paint for areas exposed to UV light to avoid this defect.

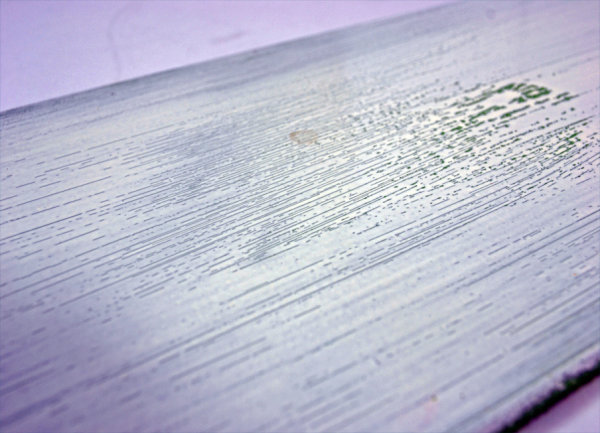

Flaking

Image Source: Fitz-Coatings

Flaking of the painted film occurs due to improper application of primer coat over putty. It can also occur due to shrinkage or expansion of a surface.

Typically, it occurs due to the presence of moisture underneath the coating. If applied over oil, dirt, grease, or a poorly prepared, powdery surface, chances of flaking increase.

In addition, it also occurs when the bond between surface and paint film is poor. Its prevention requires surface cleaning and rubbing with abrasive paper before painting.

Cracking

Image Source: Hirshfields

Cracking defect refers to the chipping of the paint film. It is often visible on both exterior and interior surfaces. This defect mainly occurs in paints containing inadequate adhesion and flexibility. Premature application of the final coat before the previous coat has completely dried also contributes to cracking.

On the exterior surface, cracking occurs due to prolonged exposure to the atmosphere. However, on interior walls, this defect mainly occurs due to faulty application of paint and insufficient drying time between coats. In addition, it also occurs on wooden surfaces.

Cissing

Image Source: Brewers-Decorator-Centres

Cissing refers to a defect in which freshly applied paint recedes from the surface. Moreover, it leaves small craters or bare areas on the entire surface resulting in irregularities. Usually, cissing occurs due to contamination of the surface.

Moreover, this defect may also occur when water-thinned paints are applied over glossy oil-based coatings. Its prevention becomes possible by cleaning or scrubbing off the oil-based coatings before the application of water-thinned materials. When cissing has occurred, allow the paint to harden before rubbing and recoating it.

Sagging

Image Source: British Paints

The surface, when painted with a thick layer of paint, results in the film running downwards. This results in sagging. Similar to running, sagging occurs considerably quicker.

It also identifies as curtaining or running of paints. Additionally, its common causes include uneven application, flat surfaces, or over-application to mouldings and rough surfaces. Therefore, avoid heavy coats in order to prevent sagging.

Saponification

Image Source: Mitchell Wright on LinkedIn

Saponification refers to the effect of alkali on oil-based paints in the presence of moisture. In this case, the formation of soap patches occurs on the paint surface. Eventually, this leads to peeling.

In mild cases, the paint softens and discolours. However, in severe cases, the paint may be completely destroyed.

Alkali in damp cement, concrete, lime plaster, asbestos, or similar materials and contact with alkaline solutions will cause saponification of oil-based paints.

In the event of saponification, scrubbing, washing, and drying of the surface before repainting becomes necessary.

Top paint companies in India

Asian Paints

This paint brand has come a long way since its small beginnings in 1942. Asian Paints became a corporate force and a leading paint company in India with products like Tractor Emulsion & Apcolite.

This paint company manufactures a wide range of paints for decorative and industrial use in India. Moreover, it offers wall coverings for exterior and interior, wood and metal, adhesives, and services under its portfolio.

Berger Paints

Berger Paints India Limited is the second largest paint company in India with a consistent track record of being one of the fastest-growing companies for the past few years.

This paint company in India manufactures interior and exterior wall coatings, undercoats, waterproofing solutions, exterior textures, emulsion, and finishes including oil, metal, wood, and glass.

Nerolac Paints

Nerolac Paints, a leading paint company in India offers a wide range of colors & decorative wall solutions for homes & offices. It is a subsidiary of Kansai Paint of Japan.

It offers a wide range of industrial paints, oil-based, enamel, emulsion, powder coatings, coil coatings, interior, and exterior coatings, and colours. Moreover, it also manufactures wood and metal surface paints and automotive coatings.

Nippon Paint

Nippon Paint, a company in India, produces high-quality products with an emphasis on innovation and eco-friendliness. Choose your wall design with its colour catalogue for interior, exterior, waterproofing solutions, wood and metal, primers, emulsion, oil paint and undercoats, and construction solutions.

Dulux Paint

An internationally available brand, Dulux, is the most popular company for the decorative paint and coatings company in India while the performance coatings business provides solutions to many industries and sectors.

Indigo Paints

Started in the year 2000 in India, Indigo Paints covers most segments of water-based products like exterior emulsions, interior emulsions, distempers, primers, enamels, putties and primers, oil base, wood coatings, etc. for homes and offices.

Shalimar Paints

Shalimar Paint Color & Varnish Company was established in 1902 in India. Rapidly expanding presence and reach, Shalimar has become a leading paint company in India.

The brand manufactures emulsion, oil-based interior and exterior paint, distemper, enamel, putty, primer, varnish, etc.

Conclusion

Painting is a fast and inexpensive alternative to revamp an old room. It gives the space a breath of fresh air making your house more inviting.

Since walls enhance the appearance of buildings, it is an ordinary component of any renovation project. However, wall paints have supplementary uses apart from amplifying looks. Knowing the performance characteristics of each type is primary for their selection.

In addition, there are various types of wall paints with totally different applications. The reasons to use paint in construction include visual appeal, surface durability, chemical protection, and protection from termites.

Therefore, as an architect, it is pivotal for you to know all about paints since they play a major role in building construction.

After reading this article, you must be certain that each classification is designed for specific applications. Therefore, it is important to understand their properties in detail. Efficient selection of ideal wall paint reduces project costs and improves performance.

Painting your house can be an expensive and tedious task. Hence, check the paint by comparing its characteristics to the characteristics of ideal wall paint. If it is not of good quality, the paint will deteriorate quickly and will not serve its purpose properly.

Lastly, for your next project, choose from the most famous and trusted paint companies in India.