MASK architects, renowned for its innovative maritime design, proudly presents ‘ONYX H2-BO 85,’ the world’s inaugural 85-meter superyacht propelled by onboard hydrogen production. This remarkable vessel not only heralds a new era of sustainability in the yachting industry but also sets new standards for luxury and eco-consciousness.

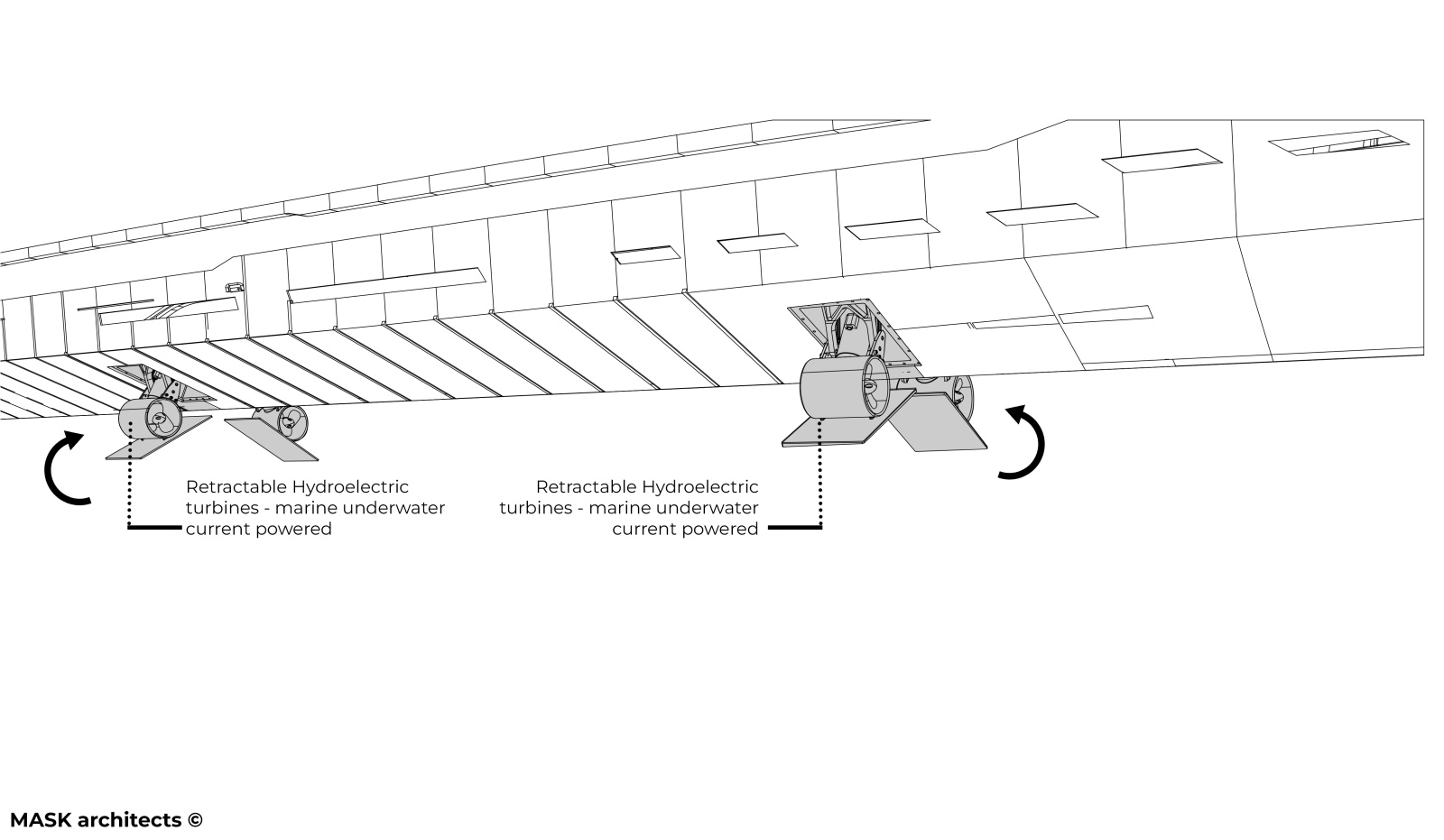

This groundbreaking vessel ingeniously combines hydrogen production through electrolysis with hydroelectric turbines, providing a unique solution for sustainable power generation during short cruising distances while minimizing environmental impact.

By harnessing the energy-efficient process of electrolysis through hydroelectric turbines, ‘ONYX H2-BO 85’ emits no harmful gases locally, significantly enhancing the marine environment and reducing the yacht’s ecological footprint during sailing. Hydroelectric turbines efficiently capture the kinetic energy of surrounding water, outperforming conventional generators in terms of energy efficiency.

This clean energy approach enables ‘ONYX H2-BO 85’ to generate and store hydrogen onboard, eliminating the need for large fuel reserves and providing easily accessible energy during low-speed sailing or anchoring. Consequently, this reduces the yacht’s reliance on fossil fuels, resulting in substantial long-term cost savings amid rising fuel prices and stable hydropower costs.

‘ONYX H2-BO 85’ seamlessly fuses luxury and sustainability. The yacht’s interior exemplifies modern elegance, featuring bespoke design solutions that cater to the most discerning tastes. From opulent cabins to lavish lounges, every space radiates an aura of refined sophistication, offering passengers an unparalleled onboard experience.

Renowned interior designers have painstakingly curated every detail, combining sumptuous materials, cutting-edge technology, and sustainable elements to create an ambiance that is both inviting and eco-conscious. What sets ‘ONYX H2-BO 85’ apart is its pioneering onboard hydrogen production system, which utilizes seawater to generate hydrogen gas through a process known as electrolysis.

Producing Hydrogen Onboard a Yacht Using Seawater: A Step-by-Step Guide

- Seawater Intake: Install a seawater intake system on the yacht to draw seawater from the surrounding environment. This system includes a pump and filters to ensure that the seawater used is free from contaminants that could damage the electrolysis equipment

- Pre-Treatment: Seawater typically contains impurities like salt, minerals, and other particles. Before electrolysis, it’s essential to pre-treat the seawater to remove these impurities. This can be accomplished using filtration and desalination systems.

- Electrolysis Chamber: Set up an electrolysis chamber onboard the yacht. This chamber contains two electrodes, typically made of materials like platinum or iridium, which are immersed in the pre-treated seawater. These electrodes are connected to a power source.

- Apply Electrical Current: Pass an electrical current through the seawater by connecting the electrodes to a power source. This electrical current causes the water molecules to break apart into hydrogen and oxygen gases.

- Collection and Storage: Collect the hydrogen gas that forms at the cathode (negative electrode) and separate it from the oxygen gas produced at the anode (positive electrode). Store the hydrogen in suitable containers or tanks.

- Safety Measures: Implement safety measures, as hydrogen is a highly flammable gas. Adequate ventilation, leak detection systems, and safety protocols should be in place to handle and store hydrogen safely.

- Use of Hydrogen: The produced hydrogen can be used as a fuel source for various purposes on the yacht, such as powering engines, generators, or fuel cells. It can also be stored as a backup power source.

It’s important to note that while producing hydrogen from seawater is feasible, it requires specialized equipment and expertise. Additionally, energy is required to power the electrolysis process.

Therefore, integrating a renewable energy source, such as solar panels or wind turbines, into the yacht’s power system is advisable to make the process more sustainable. Source by MASK architects.

Design: MASK architects

Principal Designers: Danilo Petta, Oznur Pinar Cer

Collaborators: ALCHEMIST Studio

Team: Cinzia Nieddu, Alberto Barroccu, Simone Sanna, Carlo Spano

Year: 2023

Images: Courtesy of MASK architects